- Top: 1Step on: 8

annealed steel wire

People involved | Date:2025-08-14 05:31:59

Related articles

Ultimately, the decision to employ an automatic spray painting machine is one that underscores a commitment to quality, efficiency, and forward-thinking production strategies. Not only does it signify an alignment with cutting-edge technology, but it also positions your business as a leader in delivering products that meet high standards in craftsmanship and environmental consideration.

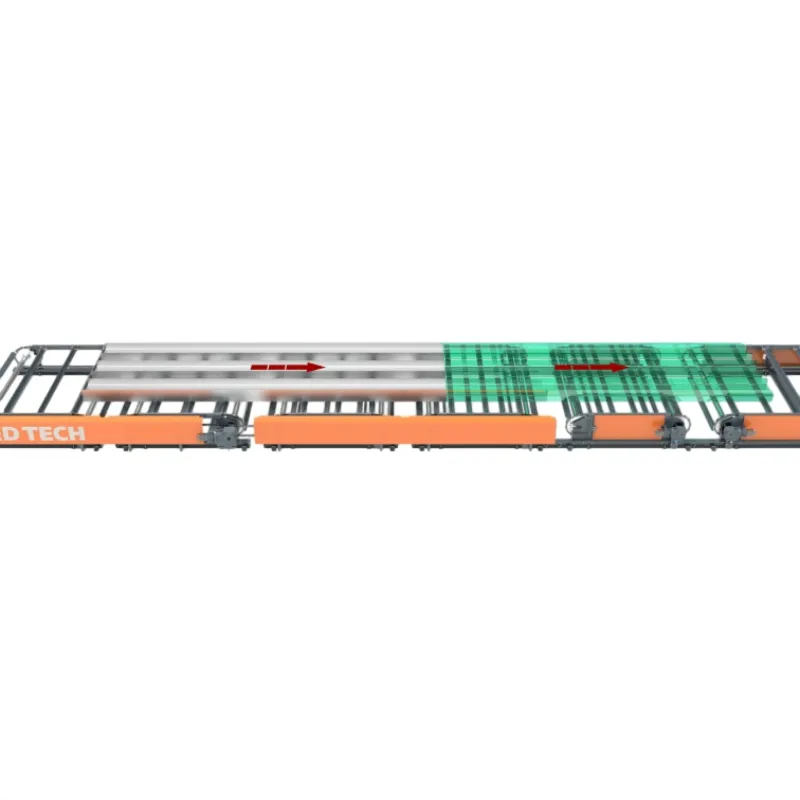

The automatic spray painting machine is customizable to fit your specific project needs, from adjusting spray patterns to optimizing paint flow rates. With user-friendly interfaces, your team can easily operate the machine, minimizing downtime and maximizing output. Investing in our automatic spray painting machine project means investing in the future of your business.

However, the operation of forklifts, particularly in busy environments like ports, requires strict adherence to safety protocols. Operators must be properly trained to handle these powerful machines, and regular maintenance must be conducted to ensure that the machines function properly and safely. This includes inspecting lifting systems, brakes, and tires, as well as providing adequate training to minimize the risk of accidents in the workplace.

1. Research and Development Conduct thorough research on the latest robotic and spraying technologies, assessing various paint materials and their compatibility with automation.

Features of Robotic Welding Arms

The Advancements and Importance of Automatic Ink Dispensers

Conclusion

3. Reduced Damage Containers protect materials during transport, helping to minimize damage due to impact or exposure to elements, thus lowering overall replacement costs.

Comment area